Supply Chain Breakdown Brings Unprecedented Shortages

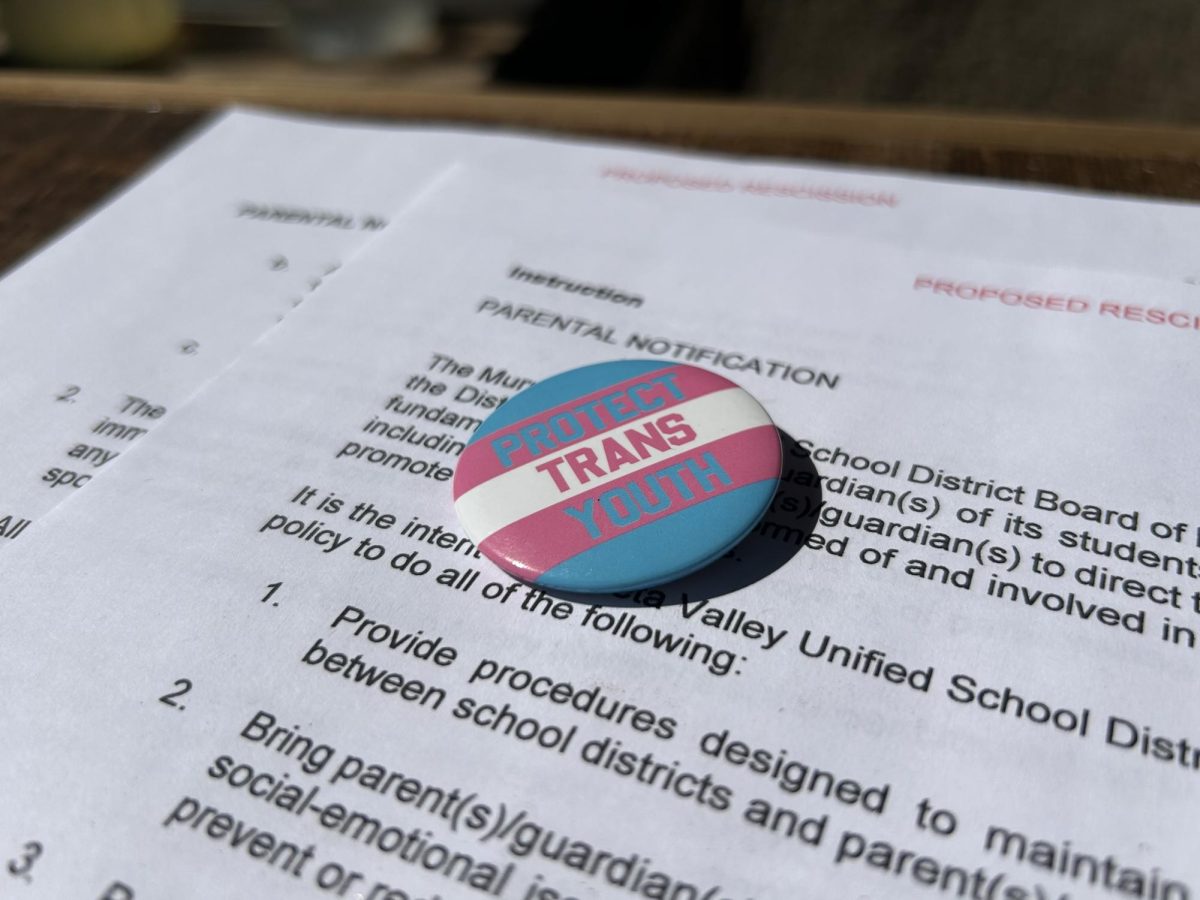

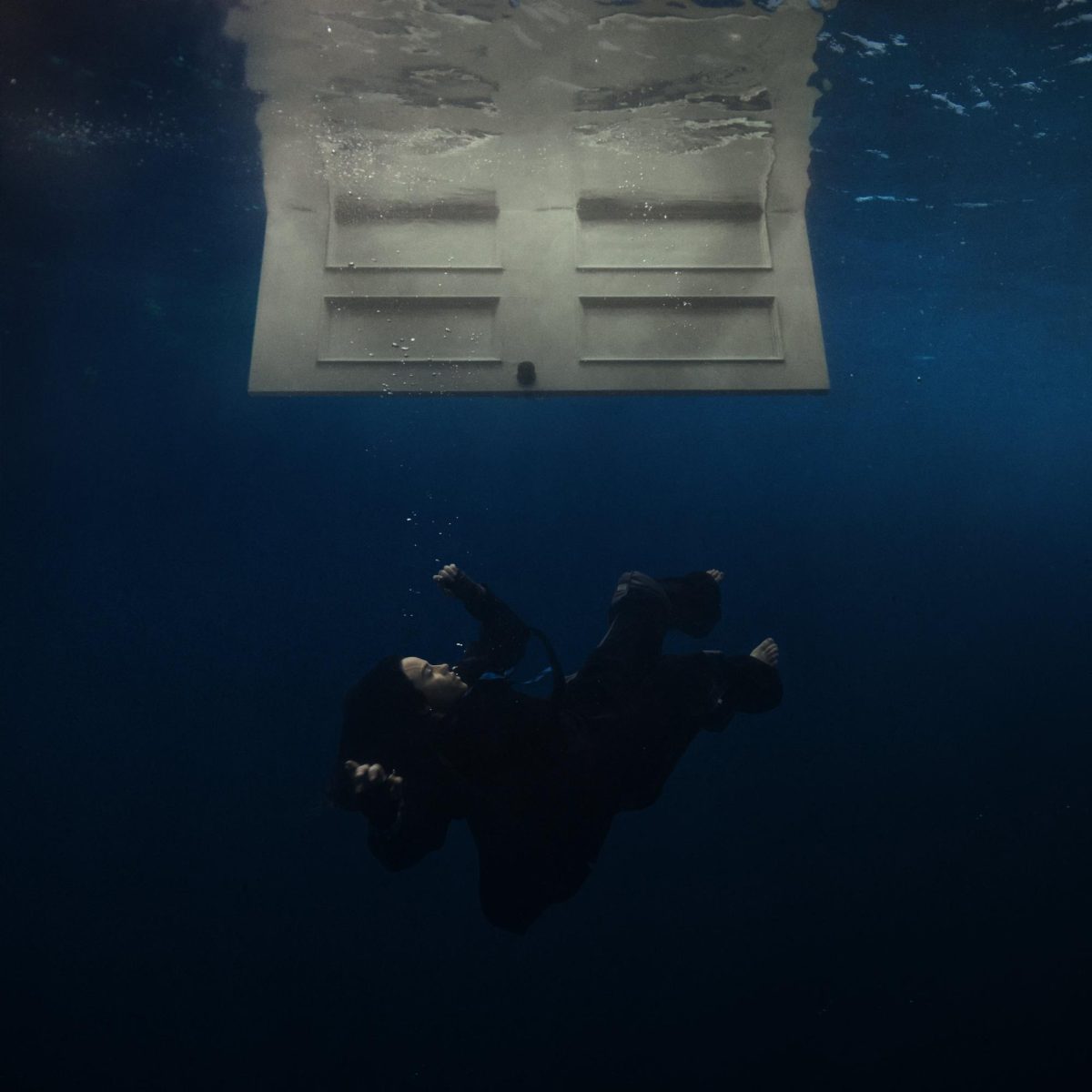

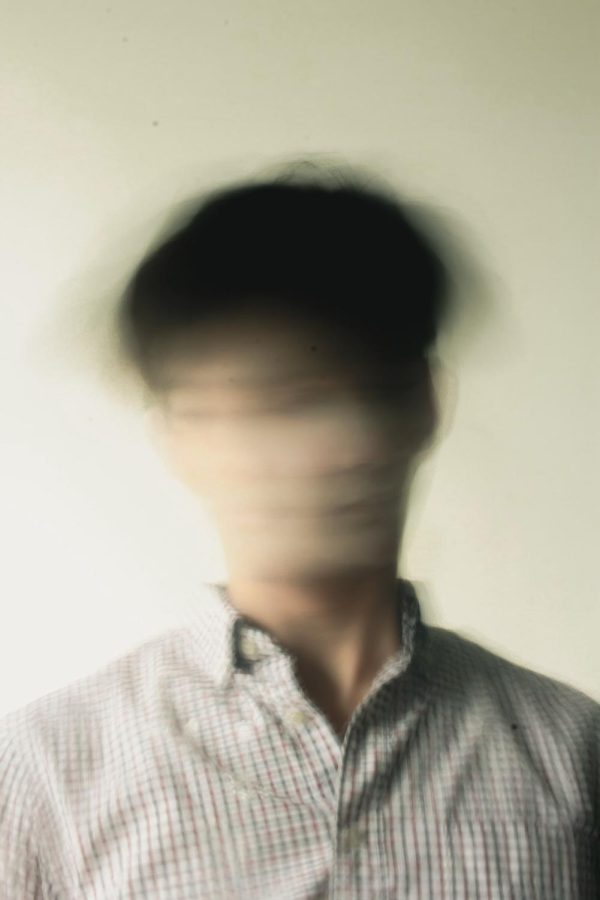

Containers sit waiting to be picked up at the ports in Los Angeles and Long Beach due to the supply chain backup

November 16, 2021

The scene of hundreds of enormous container ships off the coast of California waiting to dock and unload their cargo, continues to bring fear and uncertainty about the U.S. and the world’s economies. Empty store shelves are something many Americans remember from the early days of the pandemic in 2020, when things like toilet paper were hard find because people panic shopped and cleared store shelves. Nearly 2 years later this is happening again, but the problem lies in a supply chain bottleneck. It is affecting everything from cell phones and cars, to basic household goods.

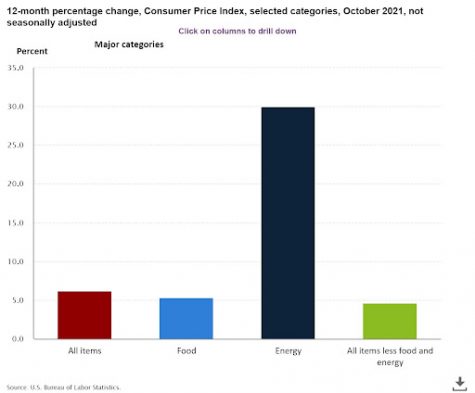

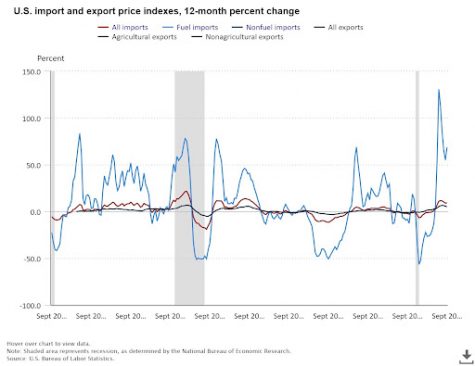

In 2019, 14.6 % of goods relevant to GDP (Gross Domestic Product) were imported to the U.S. Of these products, the most affected are electronics, cars, food, and building materials. Along with many goods being outright unavailable in many parts of the country, the prices of the things you can purchase have increased dramatically. The price of diapers has gone up by 9%, clothes by 4.2%, new cars by 7.6%, and food by 4.6% according to the Bureau of Labor Statistics. The cause, as well as the solution to this problem, is a highly debated topic amongst economists, industry experts, and world leaders.

Covid-19 and the subsequent shutdowns has caused many companies to ratchet down the production of goods due to decreased demand. Now, as people resume their (somewhat) normal lives, supply is struggling to meet pre-pandemic demand. The shortage of microchips was the first indicator that something was wrong. Many of the semiconductor chips are manufactured in China; which shut down many of the factories manufacturing these chips, due to Covid. Along with tighter border restrictions, things like cell phones and cars were among the first products affected. The small number of chips that were making it to their intended destination were also being stockpiled by companies, further exacerbating the shortage and driving up the price of any product that requires these chips as key components. If one were to walk on to a car dealership lot you would visibly see the effects, as there are little to no new cars available for sale.

The Consumer Price Index has risen 5.4% in September, compared to last year. This marks the highest rise since 2008 when the subprime mortgage crisis hit and plunged the economy into a recession. “After weeks of negotiation and working with my team and with the major union and retailers and freight movers, the Ports of Los Angeles — the Port of Los Angeles announced today that it’s going to be — begin operating 24 hours a day, 7 days a week,” President Biden remarked on October 13th. Biden urged the two largest ports in the country to help ease the bottleneck. Over 40% percent of all imported goods to the United States come through the ports of Los Angeles and Long Beach.

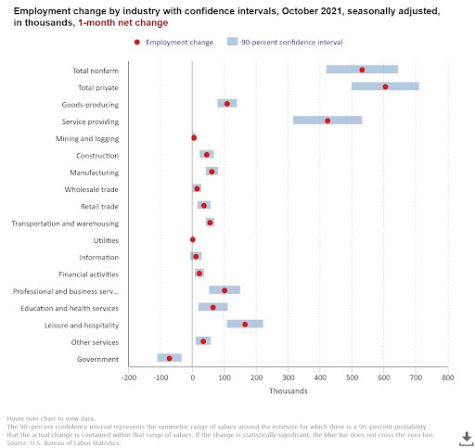

Officials and companies are looking for complicated answers to why this is happening. Although the simplest way to explain why there is this bottleneck in the supply chain is that there are simply not enough warehouse workers and truck drivers to meet this demand. About 4.3 million Americans quit their jobs in August of 2021; the most in the history of the Bureau of Labor began tracking this data in 2000. Companies like Amazon, Walmart, and even Target have had trouble getting people to come back to work. This means that there are many consumer goods just sitting around in warehouses waiting to be shipped, with no one to do the shipping. Companies have gone as far as to charter their own ships in order to attempt to mitigate the effects of the shortage. This sentiment is also felt in the trucking industry. There are currently 231,000 job openings for drivers according to the Bureau of Labor Statistics.

The bottom line is, this is a perfect storm of events which has led to an unprecedented bottleneck of the supply chain, caused by uncertainty about the economy because of covid-19, and a shortage of people willing to work these crucial jobs. In many cases, companies are not willing to pay a fair wage, thus skyrocketing demand from consumers, along with the rising cost of goods, have all played a role in this crisis. It’s like a group of cars on the freeway all suddenly stopped for a split second, thus causing the domino effect of the cars behind them having to also stop, and so on and so forth. That is what has happened to the supply chain. The chain of events has left store shelves empty, and the indication is that it will get worse before it gets better.

The bottom line is, this is a perfect storm of events which has led to an unprecedented bottleneck of the supply chain, caused by uncertainty about the economy because of covid-19, and a shortage of people willing to work these crucial jobs. In many cases, companies are not willing to pay a fair wage, thus skyrocketing demand from consumers, along with the rising cost of goods, have all played a role in this crisis. It’s like a group of cars on the freeway all suddenly stopped for a split second, thus causing the domino effect of the cars behind them having to also stop, and so on and so forth. That is what has happened to the supply chain. The chain of events has left store shelves empty, and the indication is that it will get worse before it gets better.

The best thing consumers can do is not buy things unless they absolutely need them. The more orders companies get, the more things get backed up, which will further cause prices to rise, and costs are being passed onto consumers. That, unfortunately, is not an option for things like food and medicine. The government and the private sector will have to work together to solve the problem before it becomes catastrophic for many Americans. Catastrophic doesn’t mean not being able to buy Christmas gifts, it means, potentially not being able to get food and essential goods in many parts of the country. “Strengthening our supply chains will continue to be my team’s focus,” said Biden. “If federal support is needed, I will direct all appropriate action, and if the private sector doesn’t step up, we’re going to call them out and ask them to act.”

The House of Representatives recently passed a 1.2 trillion-dollar infrastructure bill on November 5th, sending it to the president’s desk for signature. Much of what is in the bill is direct funding to help strengthen the supply chain and alleviate the current crisis thus preventing this from happening again. The bill includes 17 billion dollars for ports, 25 billion dollars for airports, and 110 billion for roads, bridges, and other major projects. Further action by both federal, state, and local governments will likely be needed along with the company’s support. Early indications are that the supply chain bottleneck could continue well into 2022.